Light curtains for measurement, automation and control

3 models available in relations to the outputs.

The Metronconf Configuration software for PC, with graphic user interface, is supplied with each light curtain (models A and B only).

Beam spacing available: 5 … 75 mm.

Controlled height: 140 … 2525 mm.

Max. range:

- 2 m – models with beams spacing 5 mm

- 6 m – models with beams spacing 25, 50, 75 mm

- 16 m – models with beams spacing 10, 30mm

Connections with M12 and M16 connectors. Up to 50 m of electrical connections with unshielded cables.

Possibility of connection of up to 8 Metron B light curtains as nodes of an RS-485 serial line for simultaneous detection of multiple dimensions and complex measurements.

-

Controlled heights (mm) 140 … 2525 Beam spacing (mm) 5, 10, 25, 30, 50, 75 Max. range 2 m for models with beam spacing 5 mm

6 m for models with beam spacing 25, 50, 75 mm

16 mfor models with beam spacing 10, 30 mmMeasurement time (2,25 ms + 70 µs x n raggi) x 2 Synchronisation between emitter and receiver Optical or via cable, selectable Signalling 7-segment display and LEDs for operating status and light curtain self-diagnosis Power supply (VDC) 24 ± 20% Max. length connection cables between light curtain and interface 50 m Operating temperature (°C) 0 … 55 Protection rating IP 65 Fastening mode Back slot, side slot, or to the top and lower end with swivel brackets Cross-section dimensions (mm) 35 x 45 mm CHARACTERISTICS OF METRONCONF CONFIGURATION SOFTWARE

Possibility for on-line display on PC screen during operation (via RS-232) to display the status of each individual beam and solid state outputs.

Configurable parameters:

- Operating logic (conditions for output activation),

- parameters of the RS-485 serial line (transmission method, baud rate, parity, start-stop characters, binary, hex, ascii format, etc.).

- 2014/30/EU: Electromagnetic Compatibility Directive

- 2014/35/EU: Low Voltage Directive

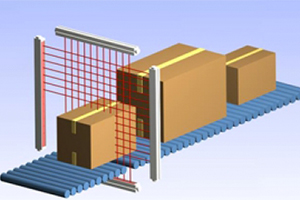

- Measurement of the height of objects in transit on conveyor systems

- Quality control: verification of presence, absence or position of holes

- Two-dimensional detection of objects in transit on conveyor systems with use of 2 light curtains

- Automatic warehouses

- Measurement and identification of cylinders of various sizes

- Detection of position and profile of pieces in automatic painting systems

- Loop control

- Quality control: verification of correct positioning of objects

- Detection of overall dimensional limits of vehicles for vehicle handling in automatic parking garages

- Measurement of the width and position of panels or sheets of material in transit on roller units or conveyor belts

RANGE

Recent Comments